SANDWICH PANELS

"Nazarian Cooling Systems" company is engaged in importing high-quality sandwich panels and is the official representative of Noboughsarmayesh company in RA. According to the data of the Statistical Committee of the Republic of Armenia in 2021 about 22% of the import of sandwich panels in RA was carried out by "Nazarian Cooling Systems" company.

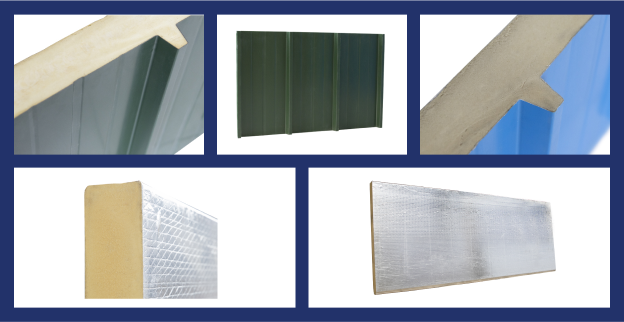

Noboughsarmayesh polyurethane foam sandwich panels are composed of two powder-coated galvanized sheets with polyurethane foam sandwiched between them. We have 4 types of sandwich panel production:

- Ceiling sandwich panels

- Wall sandwich panels

- Roof sandwich panels

- Floor sandwich panels

COMPARATIVE ADVANTAGES:

Speed:By using polyurethane foam sandwiches, it is possible to build about 150 m2 of construction area per day, which is ten times fast than building with stone or blocks.

RESISTANCE TO EXTERNAL FACTORS:

These sandwiches withstand large temperature fluctuations, from -180°C to +140°C. Polyurethane foam has an ability to absorb water vapor from the low air conditions. It does not absorb moisture and, as a result, does not lose its heat transfer properties, does not collapse, mold does not appear on it, bacteria and fungi do not multiply.

POLYURETHANE FOAM IS VERY LIGHT.

One cube metr of polyurethane foam weighs only 42 kg, which saves the time and cost needed for the sandwiches’ transportation, construction of foundations and other construction works.

Sandwiches with polyurethane foam, being an environmentally friendly product, are not interesting for rodents and insects.

Sandwiches with polyurethane foam have a variety of colours.

SANDWICHES WITH POLYURETHANE FOAM ARE USED IN THE CONSTRUCTION OF VARIOUS BUILDINGS.

- livestock farms and warehouses

- food and medical complexes

- offices and shopping centres

- sports and entertainment facilities

- buildings and structures of any type and size

- refrigerators, built-in refrigerators in cars.

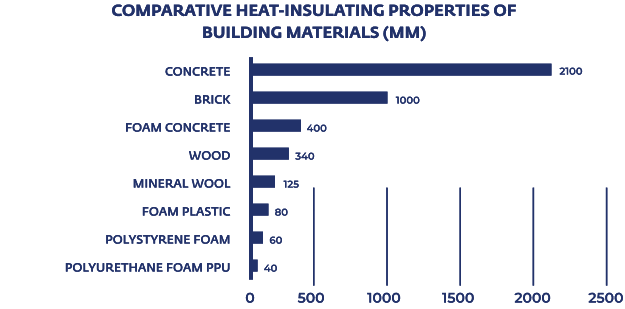

The 40 mm thick polyurethane foam sandwich panel is equivalent to 2100 mm concrete and 1000 mm brick in terms of its thermal insulation properties.

| Characteristic | |

| Powder coated galvanized sheet thickness | 0.5mm |

| Thickness of panels | 50-200mm |

| Density (kg/m3) | 42 |

| Thermal conductivity W/(m2*K) | 0.025 |

| Fire resistance | B3 |

| Sound insulation (db) | 35 |

| Comparative heat-insulating properties of building materials (mm) | |

| Polyurethane foam PPU | 40 |

| Polystyrene foam | 60 |

| Foam plastic | 80 |

| Mineral wool | 125 |

| Wood | 340 |

| Foam concrete | 400 |

| Brick | 1000 |

| Concrete | 2100 |